What is Automated Packaging Equipment and Its Benefits?

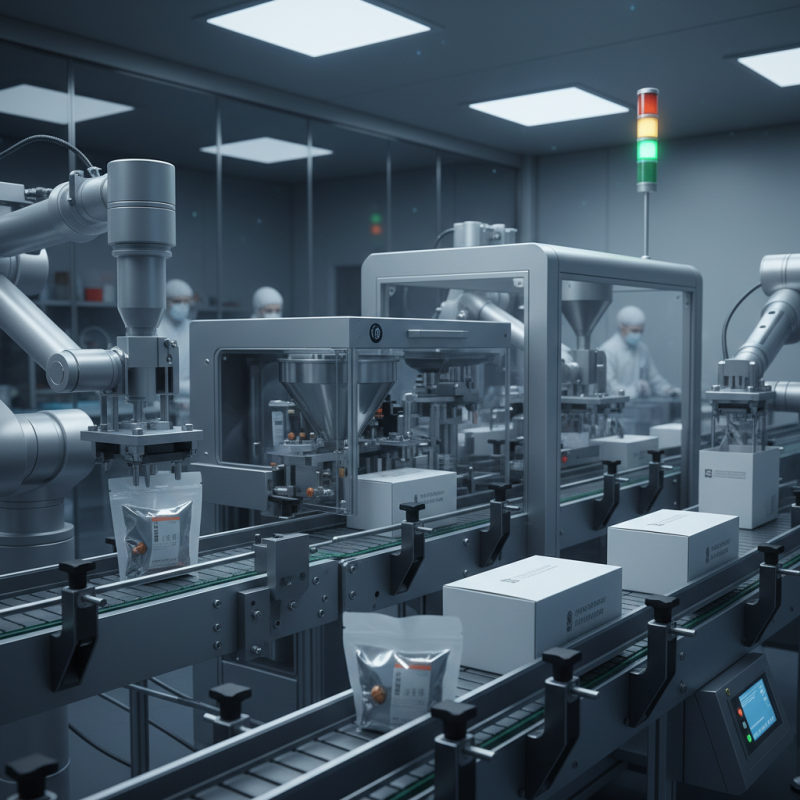

Automated packaging equipment plays a crucial role in modern manufacturing. This technology streamlines the packaging process, enhancing efficiency and accuracy. It reduces labor costs and minimizes human error. Many industries benefit from this advancement, particularly food and pharmaceuticals.

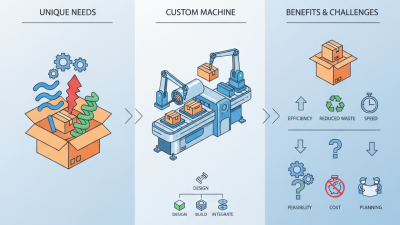

As businesses grow, the need for speed increases. Automated packaging can meet this demand effectively. It adapts to various product types and sizes, making it versatile. However, implementing such equipment can be a challenge. Companies must consider costs and training.

While automated packaging offers numerous advantages, some drawbacks exist. Dependence on machinery can lead to operational issues if the equipment fails. Regular maintenance is essential to ensure smooth functioning. Businesses need to weigh the pros and cons carefully before investing in automated packaging equipment.

What is Automated Packaging Equipment?

Automated packaging equipment plays a crucial role in modern manufacturing. It enhances efficiency and accuracy in packaging processes. This equipment includes machines for filling, sealing, and labeling products. According to a report by MarketsandMarkets, the global automated packaging market is projected to reach $79 billion by 2025. This shows significant growth driven by increasing demand for packaged goods.

Tips: Regularly maintain your equipment. Regular servicing can prevent unexpected breakdowns. Check for wear and tear to ensure long-lasting performance.

Efficiency is one of the main benefits of automated packaging. It reduces labor costs and increases production rates. For instance, automated systems can operate at speeds of up to 200 packages per minute. However, companies must also assess the transition costs. Integrating new equipment can be expensive and time-consuming.

Tips: Conduct a cost-benefit analysis before investing. Understanding the ROI can help in making informed decisions.

Automation brings precision but requires skilled operators. Without proper training, mistakes can occur. Ensuring that staff are well-trained is essential for maximizing productivity. Investing in ongoing training programs is a smart strategy for long-term success.

Key Components of Automated Packaging Systems

Automated packaging systems are designed to streamline the packaging process. These systems feature key components that enhance efficiency and productivity. One important component is the conveyor belt. This machinery transports products smoothly from one area to another. It reduces manual handling, but can sometimes struggle with fragile items.

Another crucial part is the filling machine. These machines accurately dispense products into containers. They can handle different sizes and types of products, ensuring consistency. However, the calibration may occasionally require adjustments, which can slow down production.

Sealing machines are also vital. They protect products by creating airtight seals. This is critical for maintaining freshness. However, issues with sealing may arise, leading to possible product spoilage. Regular maintenance can help avoid such problems, but it requires vigilance and planning. Overall, while automated systems provide significant benefits, their implementation demands careful consideration and ongoing management.

What is Automated Packaging Equipment and Its Benefits? - Key Components of Automated Packaging Systems

| Component | Description | Benefits | Common Use Cases |

|---|---|---|---|

| Conveyors | Systems that transport products through various stages of the packaging process. | Increased efficiency and reduced manual labor. | Food packaging, electronics assembly, and pharmaceutical packaging. |

| Packing Machines | Automated machines designed to fill, seal, and package products. | Consistency in packaging, faster speed, and reduced waste. | Food packaging, cosmetic bottles, and medical supplies. |

| Labeling Systems | Equipment that applies labels to packages automatically. | Improved accuracy in labeling and compliance with regulations. | Beverage bottles, food products, and consumer goods. |

| Robotic Arms | Automated arms used for picking, placing, and handling products. | Enhanced precision and efficiency in handling products. | Assembly lines, pick-and-place operations, and end-of-line packaging. |

| Casing Machines | Machines that assemble and pack products into cases or boxes. | Streamlined packing process and reduced handling time. | Consumer goods, beverage packaging, and bulk items. |

Benefits of Using Automated Packaging Equipment

Automated packaging equipment streamlines the packaging process. It reduces labor costs and increases efficiency. With machines handling repetitive tasks, human workers can focus on more skilled activities. Speed is another advantage; products are packaged faster than manual methods allow.

Using automated systems minimizes errors. Human mistakes can lead to costly rework. Automated equipment ensures consistency in packaging. Items are sealed, labeled, and grouped accurately. This reliability enhances customer satisfaction.

However, the transition to automation requires careful planning. Initial investment costs can be high. Companies must train staff to operate new machines effectively. Adapting to these changes can be challenging. An integration plan is necessary to mitigate disruptions. Testing systems before full implementation is crucial for a smooth operation.

Common Industries Utilizing Automated Packaging

Automated packaging equipment is becoming crucial across various industries. The food and beverage sector leads the way. According to industry reports, about 72% of companies use automated solutions in packaging. This shift improves efficiency significantly. For instance, food producers can package products faster, reducing waste.

Pharmaceutical companies also leverage this technology. Their operations require precision and compliance. Automated packaging ensures each product is securely sealed and accurately labeled. Reports indicate a 30% decrease in packaging errors since adopting automation. This level of reliability builds trust with consumers.

E-commerce fulfillment centers benefit from automation too. The surge in online shopping created a demand for efficiency. Automated systems handle a high volume of orders accurately. Yet, some companies struggle to integrate new technology. Resistance to change can be a barrier. This hesitation might lead to missed opportunities in a competitive market. Balancing technology and human insight remains a challenge for many.

Automated Packaging Equipment Usage in Different Industries

This chart represents the percentage of automated packaging equipment usage across various industries. The food and beverage sector leads with 35% usage, followed by pharmaceuticals and consumer goods, which highlights the critical role of automation in enhancing efficiency and reliability in packaging processes.

Future Trends in Automated Packaging Technology

The landscape of automated packaging technology is rapidly evolving. Companies are increasingly investing in automation to streamline operations. Advances in robotics enhance efficiency and reduce labor costs. These systems can package products at high speeds, perfect for high-demand sectors.

Sustainability is becoming crucial in automated packaging trends. Many companies are turning to eco-friendly materials and processes. Innovations in biodegradable packaging are gaining attention. However, balancing efficiency with sustainability poses challenges. Not every solution has proven effective. Adapting existing machinery can be complex and costly.

As automation continues to grow, challenges remain. Workers may need new skills to operate sophisticated machines. The integration of AI and machine learning will likely reshape packaging strategies. Yet, there are risks tied to dependency on technology. Companies must navigate these complexities while meeting market demands. The future is bright but full of hurdles that need addressing.

Related Posts

-

Top 10 Automated Packaging Machines You Need to Know About in 2023

-

Top Packaging Equipment Trends You Need to Know for Your Business

-

2025 How to Choose the Best Automatic Packaging Machines for Your Business

-

How to Choose the Right Automated Packaging Equipment for Your Business?

-

2026 How to Choose the Right Industrial Packaging Machines for Your Business?

-

What is a custom packaging machine and how does it work?