2025 How to Choose the Right Conveyor Parts for Your Business Needs

In the rapidly evolving landscape of manufacturing and logistics, selecting the appropriate conveyor parts has become increasingly critical for businesses aiming to optimize efficiency and productivity. According to industry reports, the global conveyor system market is projected to grow at a CAGR of 4.2% from 2020 to 2027, driven by the rising demand for automation in various sectors, including e-commerce and warehousing. As technology advances, the components that make up conveyor systems—such as belts, rollers, and motors—have seen significant innovation, providing businesses with enhanced performance and reliability.

Understanding the specific needs of a business is essential when choosing conveyor parts. Factors such as load capacity, speed, durability, and compatibility with existing systems must be carefully evaluated to ensure that the chosen components align with operational goals. Recent studies indicate that investing in the right conveyor parts can lead to a 20-30% increase in throughput and a significant reduction in downtime, showcasing the importance of informed decision-making in this area. As companies strive to maintain competitive advantages in their respective markets, a strategic approach to selecting conveyor parts is imperative for achieving long-term success.

Understanding Different Types of Conveyor Parts for Various Industries

When selecting the right conveyor parts for your business, it is essential to understand the specific requirements of your industry. Different sectors, such as food processing, manufacturing, and warehousing, have unique operational demands that dictate the type of conveyor systems and components needed. For example, the food industry typically requires sanitary conveyor parts that can withstand frequent cleaning and comply with food safety regulations. In contrast, manufacturing operations might prioritize durable and heavy-duty components that can handle large loads and high operational speeds.

Moreover, the choice of conveyor parts can be influenced by the material types being transported. For instance, if your business handles loose materials like gravel or sand, a belt conveyor with appropriate belts that can resist abrasion is crucial. On the other hand, organizations dealing with packaging may benefit from modular plastic chain systems, which offer flexibility in layout changes and portability. Understanding these nuanced differences is the key to optimizing your conveyor system for efficiency and productivity, ultimately leading to operational success.

2025 How to Choose the Right Conveyor Parts for Your Business Needs

| Type of Conveyor Parts | Industry Applications | Material | Load Capacity (lbs) | Speed (ft/min) |

|---|---|---|---|---|

| Roller Bed Conveyor | Manufacturing, Warehousing | Steel | 500 | 60 |

| Belt Conveyor | Food Processing, Packaging | PVC | 300 | 150 |

| Chain Conveyor | Automotive, Heavy Industries | Galvanized Steel | 1000 | 30 |

| Overhead Conveyor | Assembly Lines, Paint Shops | Aluminum | 200 | 50 |

| Screw Conveyor | Agricultural, Food Processing | Stainless Steel | 800 | 20 |

Evaluating Material Durability and Performance Specifications in Conveyor Systems

When selecting conveyor parts for your business,

evaluating material durability and

performance specifications is critical to ensure efficiency and longevity. The materials used

in conveyor systems play a pivotal role in their overall performance. For instance, choose

materials that can withstand the specific environmental conditions they will be exposed to,

such as temperature fluctuations, moisture, or corrosive substances.

Durable materials can prevent costly downtime due to wear and tear, ensuring that your operations

remain smooth and uninterrupted.

In addition to durability, performance specifications such as load capacity,

speed, and frictional properties should be considered.

The load capacity must align with the weight and volume of the materials being transported to avoid

system failure. Furthermore, understanding the required speed of the conveyor will help in

selecting parts that optimize processing times. It’s also vital to consider the friction

characteristics of the conveyor parts, as they can affect the movement and stability of the materials

being handled. Thoroughly assessing these factors will empower businesses

to make informed decisions that enhance efficiency and mitigate risks associated with equipment malfunction.

Cost-Benefit Analysis of Conveyor Parts: Quality vs. Affordability

When selecting conveyor parts for your business, a thorough cost-benefit analysis is essential to balance quality and affordability. According to a market report by Grand View Research, the global conveyor systems market is expected to reach $9.45 billion by 2025, highlighting the growing emphasis on efficiency and automation in various industries. Investing in high-quality conveyor parts may have a higher upfront cost, but it can significantly reduce long-term operational expenses due to lower maintenance needs and fewer breakdowns.

For instance, a study by the Material Handling Industry (MHI) found that equipment durability and reliability directly impact production uptime, with companies reporting a 20-30% increase in efficiency when opting for quality parts. While cheaper alternatives may seem appealing initially, they often lead to higher costs over time due to increased wear and tear and the frequency of replacement. A strategic approach involves assessing the specific needs of your operations, analyzing the total cost of ownership, and considering factors such as expected life span, performance under harsh conditions, and potential downtime. This informed decision-making process can ultimately optimize your operations and improve your bottom line.

Cost-Benefit Analysis of Conveyor Parts: Quality vs. Affordability

Importance of Compatibility Between Conveyor Parts and Existing Equipment

When selecting conveyor parts for your business, ensuring compatibility with existing equipment is crucial. Incompatible components can lead to inefficiencies, increased operational costs, and even safety hazards. Before making any purchases, it’s essential to assess the specifications of your current system. This includes measurements, load capacity, and operational speed. By doing so, you can avoid costly mistakes and streamline the integration process.

Tips for ensuring compatibility include creating a comprehensive inventory of your existing equipment. This helps establish the parameters within which new parts must fit. Additionally, consult with manufacturers regarding the compatibility of specific components, as they can provide valuable insights based on their expertise and experience. Perform testing whenever possible before finalizing large orders; even slight discrepancies can affect performance significantly.

Moreover, consider the long-term implications of your choices. Selecting parts that are not only compatible but also scalable will support future growth and changes in production demands. Look for components that allow you flexibility for upgrades, ensuring that your system can evolve alongside your business needs. This approach not only secures your immediate requirements but also promotes sustained efficiency and productivity in the long term.

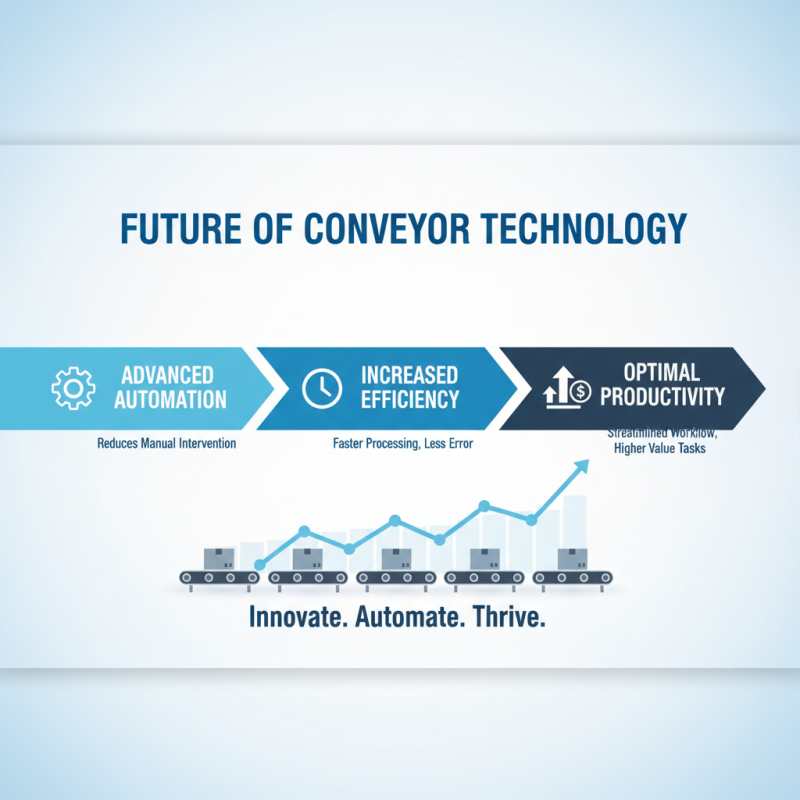

Trends in Conveyor Technology: Innovations to Enhance Business Efficiency

In the ever-evolving landscape of conveyor technology, businesses are increasingly looking towards innovative solutions that enhance efficiency and productivity. One of the most significant trends is the integration of advanced automation systems. These systems facilitate seamless operation and reduce the need for manual intervention, leading to faster processing times and minimizing the risk of human error. Implementing automated conveyors helps streamline workflows, allowing businesses to focus on higher-value tasks while maintaining optimal throughput.

Another notable trend is the use of smart technologies, such as IoT connectivity and data analytics. By incorporating sensors and monitoring devices into conveyor systems, companies can gather real-time data on performance and operational metrics. This information enables better decision-making and predictive maintenance, ultimately reducing downtime and operational costs. As the industry moves toward more sustainable practices, many new conveyor solutions are designed with energy efficiency in mind, utilizing advanced materials and drive systems that lower power consumption while maintaining high performance.

Related Posts

-

Top 5 Benefits of Using an Automated Packaging Machine for Your Business

-

2025 How to Choose the Best Automatic Packaging Machines for Your Business

-

Why Your Business Needs an Industrial Packing Machine for Efficiency and Growth

-

Innovative Material Handling Carts for Efficient Workplace Organization and Productivity

-

Top 10 Best Material Handling Equipment for Efficient Warehouse Operations

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023