10 Essential Tips for Choosing the Right Bottle Filling Machine

Choosing the right bottle filling machine is crucial for any beverage or liquid packaging operation. According to industry reports, an efficient bottle filling machine can enhance production speed by up to 30%. This significant improvement can directly impact a company's bottom line. The right equipment ensures optimal performance, minimizing waste and errors.

However, many businesses overlook key factors when making their selection. Understanding the specific needs of your production line is essential. Considerations such as fill accuracy, compatibility with different bottle sizes, and ease of cleaning can greatly influence operational efficiency. The wrong choice may lead to increased downtime and maintenance costs.

Analyzing data from various manufacturers reveals a broad spectrum of options available today. Not all machines are created equal; some may promise high speeds but falter in reliability. This inconsistency can hinder growth and customer satisfaction. Therefore, a thorough evaluation of the market, along with a testing phase, is recommended to avoid costly mistakes in the future.

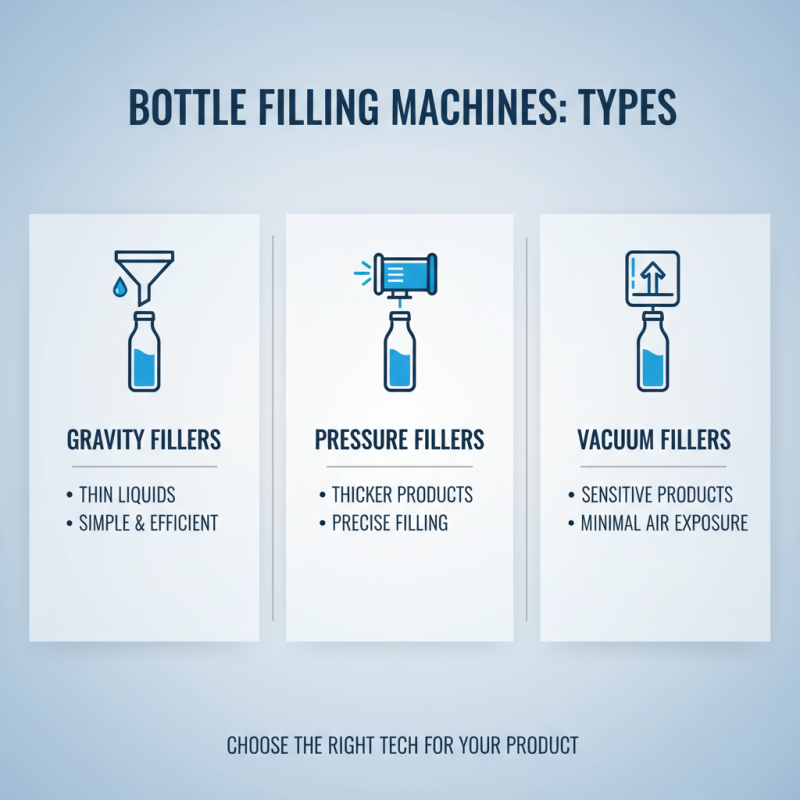

Understanding the Different Types of Bottle Filling Machines

When selecting a bottle filling machine, understanding the different types is crucial. There are several filling methods available, such as gravity, pressure, and vacuum. Gravity fillers use the force of gravity for the liquid to flow, making them simple and effective for thinner liquids. On the other hand, pressure fillers can handle thicker products and provide precise filling. Vacuum fillers are great for sensitive products, ensuring minimal exposure to air.

When choosing a machine, consider the material of your bottles. Some machines work better with glass, while others are designed for plastic. It's important to match the machine with your specific bottle type. Also, think about production speed. Does the machine meet your daily output needs? A slower machine could affect efficiency.

Tip: Always conduct a test run with your actual product. This can reveal potential issues that might not be apparent otherwise. Inspecting the machine’s features is also key. Make sure it can adjust to different bottle sizes. Flexibility is often overlooked, but it can save you money in the long run. Remember, investing in the right machine requires careful consideration and sometimes a bit of trial and error.

Evaluating Production Capacity and Speed Requirements

When selecting a bottle filling machine, evaluating production capacity and speed is crucial. The right machine should align with your business needs. Assess your current production levels. How many bottles do you fill per hour? This will help determine the speed requirements. Machines vary widely in their output capabilities, so doing this assessment is essential.

Facility size is another factor to consider. Larger machines often require more space. Make sure your production area can accommodate this. The speed of the machine also depends on its design. Some machines can fill rapidly, but they may require frequent adjustments. These adjustments can slow down production if not managed well.

Think about the type of product you are filling. Liquids and viscous substances have different filling requirements. A machine suitable for one may not work for the other. Consider testing machines before making a final decision. Sometimes, what seems ideal in theory doesn’t function as expected in practice. This reflection can save time and resources in the long run.

Assessing Compatibility with Various Bottle Sizes and Shapes

Choosing the right bottle filling machine involves careful assessment of compatibility with various bottle sizes and shapes. A recent report by Packaging Strategies highlights that nearly 30% of manufacturers struggle with machine compatibility issues. This often leads to production delays and increased costs. It's essential to evaluate the range of bottle sizes you intend to use. Machines that can handle various formats are invaluable for maximizing efficiency and flexibility.

Consider the shape of the bottles as well. For example, irregularly shaped bottles may require specialized fixtures. According to a study from the National Association of Manufacturers, nearly 25% of production downtime is due to equipment mismatch. This can be avoided by choosing a filling machine designed for versatility. Clear specifications ensure reliable operation. Don’t rush into a purchase based on features alone. Instead, review your workflow and the potential for future changes.

Also, take note of the volume capacities. Machines that only accommodate standard sizes may limit your production capabilities. In fact, 40% of bottling companies report losing clients due to inadequate equipment flexibility. The right machine should adapt not just to your current needs but also to potential growth. Take your time in assessing your options. Compatibility with various bottle sizes and shapes can dramatically optimize your production process.

10 Essential Tips for Choosing the Right Bottle Filling Machine - Assessing Compatibility with Various Bottle Sizes and Shapes

| Tip Number | Tip Description | Compatible Bottle Sizes | Compatible Bottle Shapes |

|---|---|---|---|

| 1 | Identify your production needs. | 500 ml to 2 liters | Round, Square |

| 2 | Consider the filling speed. | 100 ml to 1 quart | Round |

| 3 | Evaluate automation level. | 250 ml to 5 liters | Round, Oval |

| 4 | Assess product viscosity. | 1 liter to 10 liters | Round, Flattop |

| 5 | Check hygiene standards. | 300 ml to 750 ml | Round, Square, Flattop |

| 6 | Look for adjustable settings. | 500 ml to 2 liters | Round, Square |

| 7 | Inquire about maintenance requirements. | 250 ml to 5 liters | Round, Oval, Specialty |

| 8 | Evaluate your budget constraints. | 1 liter to 10 liters | Round |

| 9 | Research different technologies available. | 500 ml to 5 liters | Round, Specialty |

| 10 | Read customer reviews and case studies. | 100 ml to 10 liters | All Shapes |

Considering the Level of Automation and Ease of Use

When selecting a bottle filling machine, automation plays a critical role. Machines come in various levels of automation. Some require manual intervention, while others offer complete automation. Balancing efficiency and control is essential. A highly automated machine might seem appealing. However, it can lead to complexity. Operators need proper training to handle advanced systems. Sometimes, ease of use may be prioritized over all-out automation.

Consider the user interface of the machine. Intuitive controls make a significant difference. Operators should feel comfortable navigating the system. Complicated setups can lead to frustration and slowdowns. Assess whether the machine provides clear instructions. This will impact training time and overall productivity. Sometimes, a simpler machine may yield better results if it aligns more with your team's skills.

Don't forget maintenance considerations. An automated machine can be tricky to repair. If the automated features fail, it may lead to costly downtimes. In contrast, simpler machines might be easier to troubleshoot. It's wise to reflect on how often downtime can occur. A solution that looks perfect on paper might not deliver in practice. Ultimately, weigh your options carefully before making a final choice.

Reviewing Maintenance and Support Options for Long-term Operation

When selecting a bottle filling machine, long-term operation relies heavily on maintenance and support options. Regular upkeep is essential for optimal performance. According to a recent industry report, improper maintenance can lead to up to 30% loss in operational efficiency. Hence, understanding maintenance needs is crucial.

Support options also play a vital role. Look for suppliers that offer comprehensive service agreements. Many companies provide on-site assistance and remote troubleshooting. Data suggests that facilities with strong support frameworks have 20% fewer machine downtimes. This can significantly enhance productivity in high-demand environments.

Additionally, consider operators’ training as part of the support system. Educational resources help prevent operator errors. With 15% of equipment failures attributed to human mistakes, investing in proper training can mitigate risks. A solid partnership with a vendor can facilitate these elements, ensuring your operation remains smooth and effective.

10 Essential Tips for Choosing the Right Bottle Filling Machine

This chart highlights the essential features to consider when selecting a bottle filling machine, rated on a scale from 1 to 10 regarding their importance. These considerations include speed, accuracy, maintenance costs, and more, which are crucial for long-term operation and effectiveness in the production line.

Related Posts

-

10 Best Industrial Packaging Equipment for Maximum Efficiency

-

How to Choose the Right Automated Packaging Equipment for Your Business?

-

Mastering Efficiency: How VFFS Machines Revolutionize Packaging Processes for Modern Businesses

-

Top 5 Benefits of Using an Automated Packaging Machine for Your Business

-

Transform Your Workspace: The Ultimate Guide to Selecting the Perfect Material Handling Carts

-

Revolutionizing Supply Chains: The Future of Industrial Packaging Equipment Explained