2026 How to Choose the Right Small Conveyor Belt for Your Needs?

Choosing the right small conveyor belt can be a challenging task. As industry expert Jane Smith points out, "Selecting the perfect small conveyor belt requires understanding your specific needs." The decision involves various factors. These include load capacity, belt material, and dimensions.

Small conveyor belts are vital for many operations. They transport goods efficiently in tight spaces. However, businesses often overlook the importance of each element. For instance, a wrong material choice can lead to frequent breakdowns. It’s crucial to analyze the environment and the items being moved to avoid costly mistakes.

Moreover, some users might rush the selection process. This haste can result in purchasing a solution that doesn't quite fit. It’s essential to reflect on your moving requirements and operational processes. Only then will you find the ideal small conveyor belt tailored to your needs.

Factors to Consider When Selecting a Small Conveyor Belt

When selecting a small conveyor belt, various factors play a crucial role. Firstly, consider the materials you will transport. Different materials require different belt types. For instance, lightweight items may need a fabric belt, while heavier packages might need a sturdy metal design.

Another critical aspect is the belt size. Measure your workspace carefully. Ensure the conveyor fits without obstructing operations. If the belt is too wide or too narrow, it may lead to inefficiencies. You should also think about the length. A longer conveyor might save time but could require more power.

Next, assess the environment. Conveyor belts in wet or dusty settings need specific coatings. An overlooked detail can lead to maintenance issues later. Additionally, consider the speed settings you require. Too fast can cause accidents; too slow might hinder productivity. Reflect on your unique needs for the best results.

Types of Small Conveyor Belts and Their Applications

When selecting a small conveyor belt, understanding types and applications is vital. Modular belts are popular for their flexibility. They can easily maneuver around tight corners. These belts often find use in food processing due to their hygienic designs. Smaller products slide smoothly on their surface, which is critical for efficient handling.

Another common type is the flat belt. This type is simple and versatile. It supports various industries, from packaging to assembly lines. Flat belts have a larger surface area. This characteristic makes them suitable for heavy loads. In contrast, slat belts excel in transporting heavier and bulkier items. They have a solid structure, allowing stable movement.

Each type has its drawbacks. For instance, modular belts can be costly to repair. Maintenance might be challenging for flat belts in dusty environments. Users often overlook these factors. Reflecting on these aspects can lead to better decision-making. Choose wisely based on your unique requirements and environment.

2026 How to Choose the Right Small Conveyor Belt for Your Needs? - Types of Small Conveyor Belts and Their Applications

| Type of Conveyor Belt | Material | Application | Load Capacity (kg) | Belt Width (mm) |

|---|---|---|---|---|

| Flat Belt | PVC | Packaging, Assembly | 50 | 200 |

| Modular Belt | Plastic | Food Processing, Electronics | 100 | 300 |

| Cleated Belt | Rubber | Incline Transport, Bulk Handling | 150 | 400 |

| Wire Mesh Belt | Steel | Cooling, Drying | 80 | 200 |

| Timing Belt | Polyurethane | Automotive, Robotics | 60 | 250 |

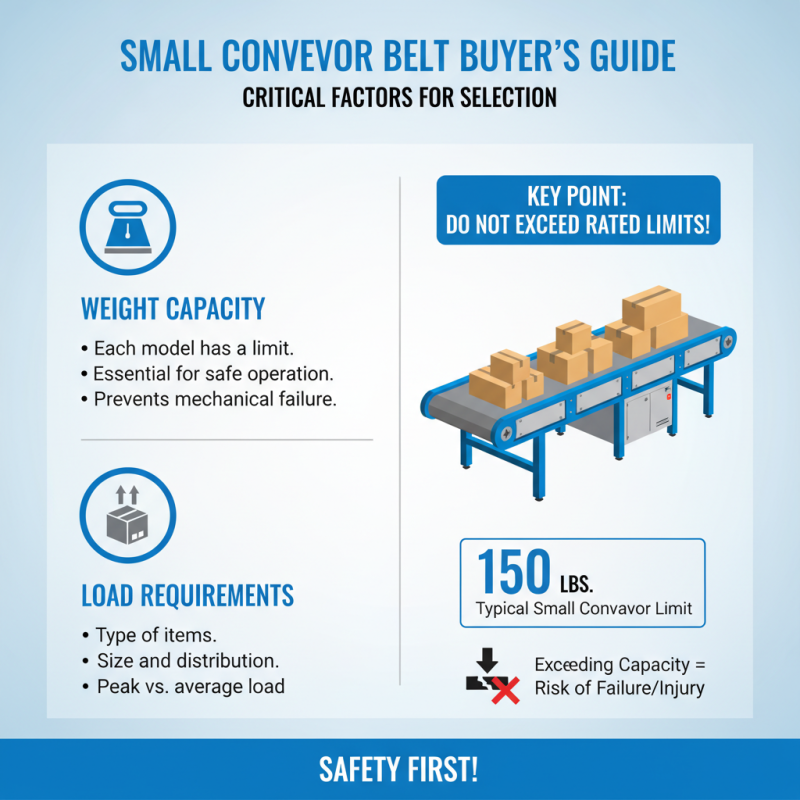

Understanding Weight Capacity and Load Requirements

Choosing the right small conveyor belt involves understanding the weight capacity and load requirements. Each conveyor belt has a specified weight limit, which is critical for safe operation. For instance, a typical small conveyor might support up to 150 pounds. Exceeding this can lead to mechanical failure or safety hazards.

Load requirements vary across industries. A manufacturing report from 2023 noted that 40% of businesses underestimated their weight needs. This miscalculation causes inefficiencies and increased wear on equipment. It’s essential to evaluate not just the maximum weight, but also the average load.

Consider the materials being transported. Fragile items require gentler handling. Also, belt width and speed impact overall performance. A study indicated that belts operating at higher speeds can experience strain if loads are not balanced. Ignoring these factors can compromise the conveyor’s lifespan. Reflection on these aspects is necessary for optimal performance.

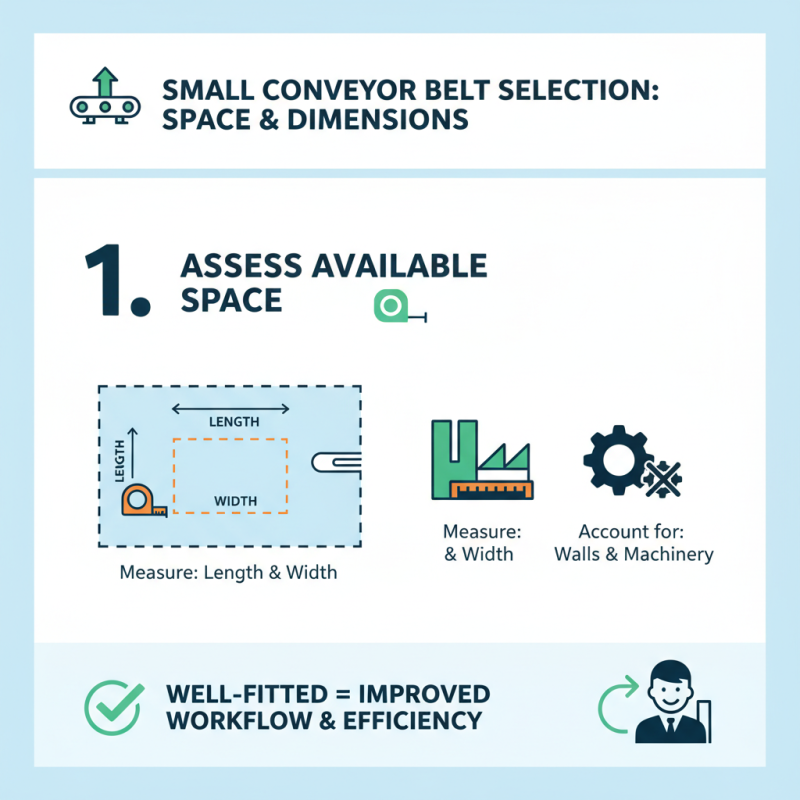

Assessing Available Space and Conveyor Belt Dimensions

When selecting the right small conveyor belt, space and dimensions are key considerations. Assess your available space carefully. Measure the length and width of the area where the conveyor will be installed. Remember to account for any obstacles like walls or machinery. A well-fitted conveyor can enhance workflow and efficiency.

Tip: Leave some extra space. A few additional inches around the conveyor helps with maintenance and adjustments. It also allows for better airflow, which may be necessary for some materials.

Consider the belt width as well. A wider belt can accommodate more material but may not fit in tighter spaces. Think about the types of products you will transport. If they are bulky or heavy, ensure that your chosen belt can handle the weight.

Tip: Don’t rush your measurements. You may want to rethink the dimensions if you notice inconsistencies. Evaluate your layout multiple times to avoid unexpected issues later. Small mistakes can create big problems. Always take the time to reflect on your choices before making a final decision.

Maintenance and Durability Considerations for Small Conveyor Belts

When selecting a small conveyor belt, maintenance and durability are crucial. These factors greatly influence efficiency and long-term costs. A well-chosen belt can reduce breakdowns and ensure smooth operations in your facility. Regular inspections help identify wear and tear early. Look for signs of fraying, excessive dust buildup, or unusual sounds.

Tips for maintenance:

- Keep the belt clean to prevent material buildup.

- Lubricate moving parts to reduce friction.

- Proper alignment is essential. Misalignment can lead to premature wear.

- Also, train staff on basic maintenance procedures. Awareness can prevent costly repairs later.

Consider the materials used in the conveyor belt. Some materials may not hold up well in certain environments. Think about the load that the conveyor will handle. Overloading can compromise the belt's integrity. Choose the right belt for the specific application. Reflect on how your choices impact the overall efficiency of your operations.

Related Posts

-

Exploring the Future of Conveyor Systems in Automation and Smart Manufacturing

-

What is a Conveyor System? Types, Uses, and Benefits Explained

-

How to Choose the Right Food Packaging Machine for Your Business Needs

-

What is Automated Packaging Equipment and Its Benefits?

-

Top 5 Custom Packaging Machine Trends Driving Efficiency and Growth in 2023

-

What are Conveyor Systems and How Do They Work?