Top Bucket Elevator Types for Efficient Material Handling Solutions?

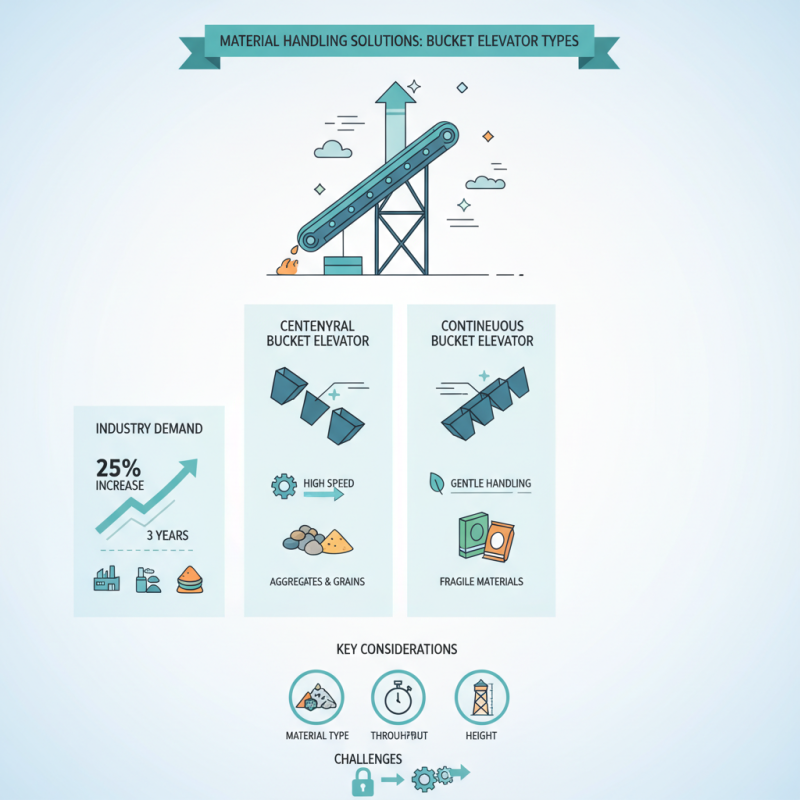

In today's fast-paced industry, effective material handling solutions are critical. The bucket elevator stands out as a key technology for transporting bulk materials. According to a report by the Conveyor Equipment Manufacturers Association (CEMA), the demand for efficient bulk handling systems has increased by 25% in the last three years. This surge highlights the importance of selecting the right type of bucket elevator for specific applications, considering factors like material type, throughput, and height.

Bucket elevators come in various designs, each tailored to meet unique operational needs. For instance, centrifugal bucket elevators excel in handling aggregates and grains, ensuring smooth flow with minimal disruption. In contrast, continuous bucket elevators provide a gentle handling option for fragile materials like food products. The optimal choice affects productivity and maintenance costs significantly. Organizations are encouraged to analyze their specific requirements to avoid inefficiencies.

While the investment in advanced bucket elevators can yield substantial returns, the challenge lies in adapting to changing demands. Many companies still hesitate to embrace newer technologies. This reluctance can hinder potential growth and lead to operational inefficiencies. In a competitive landscape, understanding the types of bucket elevators available is essential for improving overall productivity.

Key Features of Bucket Elevators for Material Handling

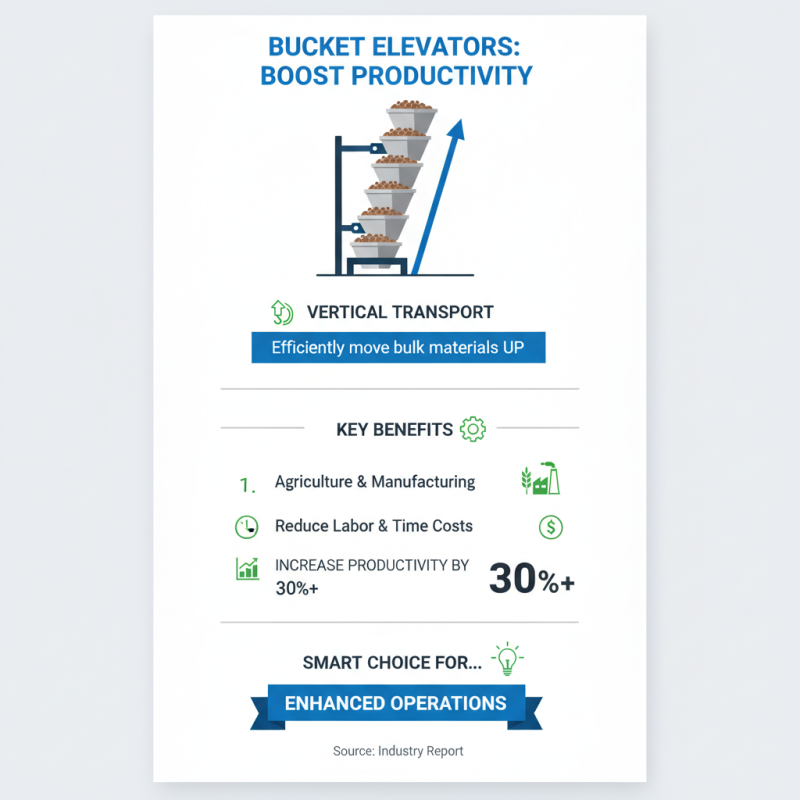

Bucket elevators play a crucial role in materials handling across various industries, including agriculture and manufacturing. They are designed for vertical transportation. These elevators can move bulk materials efficiently, minimizing labor costs and time. According to a recent industry report, bucket elevators can increase productivity by up to 30%. This makes them a popular choice for companies looking to enhance operations.

Key features of bucket elevators include their versatility, durability, and efficiency. Different materials, such as plastics or metals, can be used in construction. This enhances the lifespan and reliability of the elevators. The context of material type is vital. Not every elevator can handle abrasive or corrosive materials. Some models are too rigid to provide the flexibility needed in varying environments.

It’s important to recognize that not all bucket elevators perform equally. Some designs may lead to material spillage, reducing efficiency. Maintenance requirements vary, impacting long-term operational costs. Operators should reflect on their specific needs before selection. Ultimately, understanding these key features can lead to more informed decisions.

Types of Bucket Elevators and Their Applications

When it comes to material handling, selecting the correct type of bucket elevator is crucial. These devices come in various designs suited for specific applications. For instance, chain bucket elevators are ideal for heavy and abrasive materials, making them popular in mining and construction industries. They can handle large volumes while maintaining durability.

On the other hand, belt bucket elevators are preferred for lighter materials, such as grains and powders. Their efficiency is notable, often achieving capacities of up to 1,600 tons per hour. According to industry reports, the global bucket elevator market is projected to grow at a CAGR of 3.5% from 2022 to 2027. This expansion is driven by increasing automation in sectors like agriculture and food processing.

While bucket elevators offer impressive features, they are not without challenges. Incorrect installation can lead to inefficiencies. Regular maintenance is essential to prevent breakdowns. Analysts emphasize the importance of operator training to maximize performance. It’s clear that understanding the specific needs of operations can make or break the effectiveness of these systems.

Factors Influencing the Selection of Bucket Elevators

When selecting a bucket elevator, several factors come into play. Understanding the characteristics of the materials being handled is vital. Different materials possess unique properties. For instance, bulk density and moisture content can affect performance and speed. A heavy material may require a robust design. Light, fragile items might need gentler handling.

The application context also influences selection. Are you lifting vertically or at an angle? Is there a requirement for cleanroom conditions? These questions shape the design choices necessary for efficient operation. Consider the environment too. Dusty or abrasive materials can lead to wear and tear. This may necessitate increased maintenance and more durable components.

Cost is another critical aspect. Operators often face trade-offs between quality and price. Cheaper options may seem attractive initially. However, they might lead to higher operating costs over time. Balancing upfront costs and long-term efficiency is challenging. Real-life experience teaches the importance of thorough research before making a decision. Each project may require a unique approach. Factor in all these elements for a successful outcome.

Top Bucket Elevator Types for Efficient Material Handling Solutions

| Bucket Elevator Type | Capacity (tph) | Height (m) | Application | Key Features |

|---|---|---|---|---|

| Vertical Bucket Elevator | 50-200 | 5-30 | Grain, Feed, Cement | High efficiency, space-saving design |

| Centrifugal Bucket Elevator | 40-150 | 4-20 | Bulk Materials | Fast discharge, suitable for granular material |

| Continuous Bucket Elevator | 30-100 | 3-15 | Food, Plastics | Gentle handling, minimal product damage |

| Z-Type Bucket Elevator | 20-80 | 2-10 | Snack Foods, Nuts | Compact design, ideal for small spaces |

Maintenance Best Practices for Bucket Elevators

Maintaining bucket elevators is crucial for efficient material handling. Regular inspections can prevent unexpected failures. According to industry reports, about 30% of bucket elevator failures are due to inadequate maintenance. This statistic highlights the importance of proactive care.

Routine tasks include checking for wear and tear on buckets and belts. Regular lubrication of moving parts is vital. Use the manufacturer’s guidelines for optimal schedules. Monitoring the motor’s performance and temperature can also reveal potential issues early. These small actions can lead to significant savings in repair costs.

However, many facilities overlook minor details. Ignoring small leaks or unusual sounds can lead to bigger problems. Continuous training for staff on maintenance protocols is essential. Investing in training can enhance safety and operational efficiency. Recognizing the signs of wear can help prevent costly downtime in the long run. Balancing preventive measures with daily operations is often a challenge, yet it is necessary for sustainability.

Advantages of Using Bucket Elevators in Different Industries

Bucket elevators play a vital role in various industries, primarily for efficient material handling. They are especially useful in agriculture, food processing, and mining. According to industry research, around 25% of bulk material transport occurs via bucket elevators. Their design allows for vertical lifting, which saves floor space and minimizes handling time.

One significant advantage is their versatility. They can handle different materials, including grains, powders, and even fragile items. This adaptability helps companies streamline operations. Additionally, bucket elevators minimize spillage. A major report indicates that proper use of these systems reduces material loss by 15%.

Tip: When selecting a bucket elevator, consider the material's characteristics. Different designs cater to specific needs. Each industry faces unique challenges. In agriculture, for example, grain flow can vary seasonally. Be prepared to adapt.

However, it’s essential to address potential downsides. Maintenance can be overlooked. Equipment failures can lead to costly downtime. Operators must remain vigilant. The right approach ensures longevity and efficiency. Investing in quality components pays off.

Related Posts

-

10 Essential Tips for Choosing the Right Automatic Bagging Machine

-

2025 Top Filling Machine Innovations Enhancing Efficiency and Precision in Manufacturing

-

Top 10 Automated Packaging Machines You Need to Know About in 2023

-

The Essential Guide to Choosing the Best Material Handling Carts for Your Business Needs

-

Innovative Material Handling Carts for Efficient Workplace Organization and Productivity

-

What are Conveyor Systems and How Do They Work?